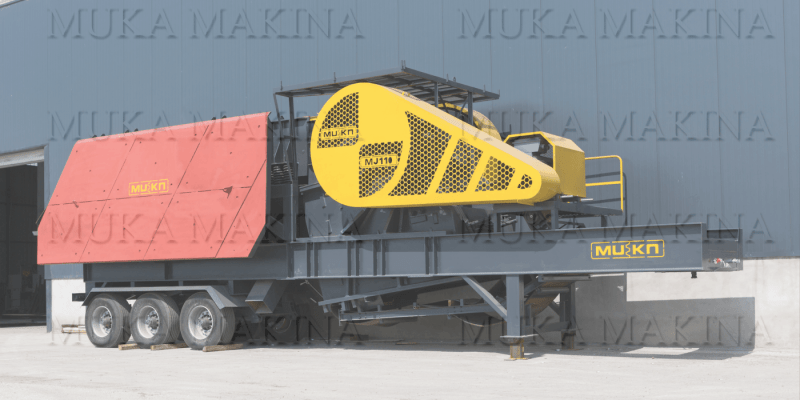

MUKA mobile Jaw Crusher Stonecrusher plant has exclusive benefits you cannot resist:

Mobile Jaw Crusher Stonecrusher solutions are also available! You just need to tell our engineer your demand, and we will equip you the right mobile crushers with low energy consumption, low cost, and high efficiency.

- Easy access to constantly moving working environment

- Shorter transportation time and lower installation cost

- Versatile body combining alternative equipment, meet customers personalized needs

- World-class quality, cutting-edge technology, appropriate price

- Easy to resale and higher resale value

Jaw Crusher Stonecrusher TECHNICAL SPECIFICATIONS |

|||

| Model | MMJ110 | ||

| Feeder Model | MF110 | ||

| Feeder Dimensions | 1120×4900 | ||

| Crusher Type | MJ110 | ||

| Width of inlet opening |

1100 | ||

| Depth of inlet opening |

850 | ||

| Discharge Band | 1000×4500 | ||

| Motor brand | GAMAK | ||

| Motor power (kW) | 150 | ||

| Length (m) | 12,8 | ||

| Width (m) | 3,1 | ||

| Hight (m) | 4,2 | ||

| Weight (kg) | 70000 | ||

| Capacity (tph) | 290 | ||

What is a Mobile Jaw Crusher?

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.

Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules that bond together more strongly, and resist deformation more, than those in the material being crushed do.

Crushing devices hold material between two parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from (fracturing), or change alignment in relation to (deformation), each other.

Emily, Morocco –

Found this exceptional product during in-depth online research—remarkable craftsmanship and innovative design. A top-tier discovery online!

YENIEXPO com –

Your review inspires us to do better! We’re committed to your happiness.

Harper, Morocco –

Remarkable buy! Exemplary features, exceptional craftsmanship.

YENIEXPO com –

We’re thrilled to receive your 5-star rating! Your satisfaction is our priority, and we’re delighted to have met your expectations.

Elijah, Ecuador –

Enduring, scope for refinement.

YENIEXPO com –

Thank you for your review! Your insights are invaluable as we strive to deliver an even better service.

Liam, Mexico –

Functional item! Moderate features, acceptable build. Meets typical functionality needs.

YENIEXPO com –

Your review is valuable to us! We’re glad you enjoyed our product and will use your insights to improve further.

Riley, Colombia –

Phenomenal investment! Unrivaled durability, exceptional quality.

YENIEXPO com –

Your recognition means a lot! We’re dedicated to evolving and meeting your expectations.

Nala, South Carolina, USA –

Decent addition. Acceptable features, standard usability.

YENIEXPO com –

Thank you for sharing your feedback! We appreciate your insights and will work on improving to better meet your expectations.

Grace, Turkey –

Outstanding gadget! Unmatched performance, superior quality.

YENIEXPO com –

We’re honored by your review! Your trust in our brand means a lot.

Michael, United States –

Superior device! Unrivaled performance, exceptional durability.

YENIEXPO com –

Thank you for your kind words! Your support inspires us to maintain excellence in every interaction.

Alexander, Algeria –

Decent device! Adequate performance, fair usability.

YENIEXPO com –

We’re grateful for your review! Your insights will guide us in our mission to continually improve.

Riley, Lebanon –

Okay item! Reasonable design, fair functionality.

YENIEXPO com –

We are grateful that you took the time out to leave us a review. Your feedback helps us to improve service for everyone.

Liam, Ireland –

Splendid investment! Unrivaled quality, supreme.

YENIEXPO com –

Your review made our day! Serving customers like you makes our work fulfilling.

Jackson, Kenya –

Remarkable find! Unbeatable performance, top-tier.

YENIEXPO com –

Your words are truly appreciated! We’re committed to ensuring your ongoing positive experience.

Daniel, Mexico –

Decent device! Reasonable features, acceptable usability. Works for everyday use.

YENIEXPO com –

Your review means a lot! We’re dedicated to addressing the aspects you’ve mentioned to ensure a more positive experience.

Abd Almuti, Egypt –

Fantastic tool! Unrivaled quality, top-tier functionality.

YENIEXPO com –

Your words are deeply valued! We’re committed to delivering excellence.

Aya, Egypt –

Fair investment! Adequate performance, fair reliability. Performs within usual ranges.

YENIEXPO com –

We value your feedback! Rest assured, we’re working on areas you highlighted to ensure a better experience.

Michael, Lebanon –

Superlative quality, truly flawless.

YENIEXPO com –

Thank you for your kind words and 5-star rating! It’s our pleasure to serve customers like you and ensure a positive experience.

Owen, Peru –

Functional addition! Adequate performance, fair quality.

YENIEXPO com –

Your review means a lot! We’re dedicated to addressing the aspects you’ve mentioned to ensure a more positive experience.

Jackson, Canada –

Remarkable buy! Exemplary features, outstanding reliability.

YENIEXPO com –

Your review inspires us to do better! We’re committed to your happiness.

Noah, United States –

Usable device! Reasonable features, acceptable usability. Fits the bill without standing out.

YENIEXPO com –

Your review is valuable to us! We’re glad you enjoyed our product and will use your insights to improve further.

Julian, Mexico –

Unbeatable quality, flawlessly executed design.

YENIEXPO com –

We’re grateful for your support! Your trust drives our commitment to improvement.

Oliver, Peru –

Outstanding purchase! Unmatched features, superior quality.

YENIEXPO com –

We appreciate your feedback! Your trust inspires us to keep excelling.

Lucas, Denmark –

This exporter is a game-changer! The products offered are exceptional, providing both value and functionality. Discovering this exporter was a stroke of luck!

YENIEXPO com –

We appreciate your feedback! Your support is vital in our journey.

Olivia, Italy –

Impressive gadget! Unparalleled value, remarkable.

YENIEXPO com –

We’re grateful for your thoughtful feedback! It guides us in crafting better experiences.

Lucas, Portugal –

Big thanks to the support team for their endless patience in answering my questions. Your assistance is greatly appreciated!

YENIEXPO com –

We love your feedback! Thank you for choosing our product!

Chloe, Angola –

Big thanks to the support team for their endless patience in answering my questions. Your assistance is greatly appreciated!

YENIEXPO com –

Thank you for your kind recognition, customer’s satisfaction is always our goal.

Gabriel, United Kingdom –

Average addition! Fair features, adequate usability.

YENIEXPO com –

Your review is appreciated! We’re committed to addressing any concerns you’ve raised for a better experience next time.

Amara, Ghana –

This manufacturer’s lineup is phenomenal! The products showcase innovation and top-notch quality. A one-stop-shop for all exceptional goods.

YENIEXPO com –

We’re thrilled to receive your 5-star rating! Your satisfaction is our priority, and we’re delighted to have met your expectations.

Sophia, United Arab Emirates –

Stellar addition! Unparalleled innovation, exceptional usability.

YENIEXPO com –

We appreciate your feedback! Your support is vital in our journey.

Logan, Australia –

Good choice, potential upgrades.

YENIEXPO com –

We are grateful that you took the time out to leave us a review. Your feedback helps us to improve service for everyone.

Mateo, Australia –

Brilliant find! Exemplary quality, truly exceptional.

YENIEXPO com –

Thank you for recognizing our commitment! Your satisfaction is our priority.

Isabella, Qatar –

Outstanding item! Exceptional quality, top-tier performance.

YENIEXPO com –

We’re thrilled to receive your 5-star rating! Your satisfaction is our priority, and we’re delighted to have met your expectations.

David, Ethiopia –

Superb find! Unbeatable value, outstanding.

YENIEXPO com –

Thank you for your kind words and 5-star rating! It’s our pleasure to serve customers like you and ensure a positive experience.

Elijah, Nigeria –

Impressive item! Unmatched quality, superior performance.

YENIEXPO com –

We’re grateful for your review! Your happiness is our ultimate aim.

Benjamin, Singapore –

Competent, room for advancements.

YENIEXPO com –

We appreciate your honest feedback! It helps us identify areas where we can enhance our product for your satisfaction.

Noah, Japan –

Excellent purchase! Unparalleled performance, superior build.

YENIEXPO com –

Your feedback is invaluable! It shapes our ongoing commitment to quality.

Akinyi, Kenya –

Acceptable gear! Adequate value, decent reliability. Works fine for its intended purpose.

YENIEXPO com –

We appreciate your honest feedback! It helps us focus on areas that need attention while maintaining our strengths.

Sophia, Brazil –

The support for this product is unparalleled. Quick responses and efficient problem-solving. Well done, team!

YENIEXPO com –

Your words are truly appreciated! We’re committed to ensuring your ongoing positive experience.

Kadija, Senegal –

Phenomenal addition! Unparalleled performance, superior.

YENIEXPO com –

Thank you for recognizing our commitment! Your satisfaction is our priority.